Position control example

using SimpleFOCShield

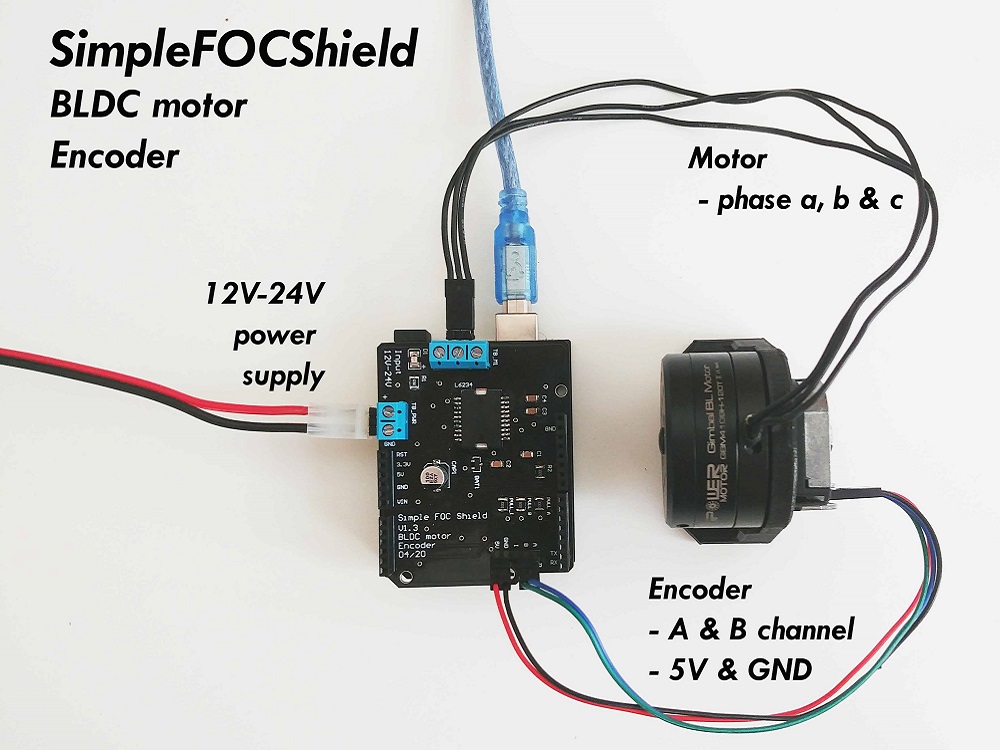

For this BLDC motor position control example we are going to be using this hardware:

Connecting everything together

For a bit more in depth explanation of Arduino UNO and SimpleFOCShield connection please check the connection examples.

For more information about the SimpleFOCShield check the docs.

Encoder

- Channels

AandBare connected to the encoder connectorP_ENC, terminalsAandB.

Motor

- Motor phases

a,bandcare connected directly the motor terminal connectorTB_M1

Small motivation :D

Arduino code

Let’s go through the full code for this example and write it together. First thing you need to do is include the SimpleFOC library:

#include <SimpleFOC.h>

Make sure you have the library installed. If you still don’t have it please check the get started page

Encoder code

First we define the Encoder class with the A and B channel pins and number of impulses per revolution.

// define Encoder

Encoder encoder = Encoder(2, 3, 2048);

Then we define the buffering callback functions.

// channel A and B callbacks

void doA(){encoder.handleA();}

void doB(){encoder.handleB();}

In the setup() function we initialize the encoder and enable interrupts:

// initialize encoder hardware

encoder.init();

// hardware interrupt enable

encoder.enableInterrupts(doA, doB);

And that is it, let’s setup the motor.

For more configuration parameters of the encoders please check the Encoder class docs.Motor code

First we need to define the BLDCMotor class with the number od pole pairs (11)

// define BLDC motor

BLDCMotor motor = BLDCMotor(11);

If you are not sure what your pole pairs number is please check the find_pole_pairs.ino example.Next we need to define the BLDCDriver3PWM class with the PWM pin numbers of the motor and the driver enable pin

// define BLDC driver

BLDCDriver3PWM driver = BLDCDriver3PWM(9, 10, 11, 8);

Then in the setup() we configure first the voltage of the power supply if it is not 12 Volts and init the driver.

// power supply voltage

// default 12V

driver.voltage_power_supply = 12;

driver.init();

Then we tell the motor which control loop to run by specifying the motor.controller variable.

// set control loop type to be used

// MotionControlType::torque

// MotionControlType::velocity

// MotionControlType::angle

motor.controller = MotionControlType::angle;

Now we configure the velocity PI controller parameters

// velocity PI controller parameters

// default P=0.5 I = 10

motor.PID_velocity.P = 0.2;

motor.PID_velocity.I = 20;

// jerk control using voltage voltage ramp

// default value is 300 volts per sec ~ 0.3V per millisecond

motor.PID_velocity.output_ramp = 1000;

//default voltage_power_supply

motor.voltage_limit = 6;

Additionally we can configure the Low pass filter time constant Tf

// velocity low pass filtering

// default 5ms - try different values to see what is the best.

// the lower the less filtered

motor.LPF_velocity.Tf = 0.01;

Finally we configure position P controller gain and the velocity limit variable.

// angle P controller

// default P=20

motor.P_angle.P = 20;

// maximal velocity of the position control

// default 20

motor.velocity_limit = 4;

For more information about the angle control loop parameters please check the doc.

Next we connect the encoder and the driver to the motor, do the hardware init and init of the Field Oriented Control.

// link the motor to the sensor

motor.linkSensor(&encoder);

// link the motor to the driver

motor.linkDriver(&driver);

// initialize motor

motor.init();

// align encoder and start FOC

motor.initFOC();

The last peace of code important for the motor is of course the FOC routine in the loop function.

void loop() {

// iterative FOC function

motor.loopFOC();

// iterative function setting and calculating the angle/position loop

// this function can be run at much lower frequency than loopFOC function

motor.move(target_angle);

}

That is it, let’s see the full code now!

For more configuration parameters and control loops please check the BLDCMotor class doc.Full Arduino code

To the full code I have added a small serial commander interface, to be able to change position/angle target value in real time.

#include <SimpleFOC.h>

// init BLDC motor

BLDCMotor motor = BLDCMotor( 11 );

// init driver

BLDCDriver3PWM driver = BLDCDriver3PWM(9, 10, 11, 8);

// init encoder

Encoder encoder = Encoder(2, 3, 2048);

// channel A and B callbacks

void doA(){encoder.handleA();}

void doB(){encoder.handleB();}

// angle set point variable

float target_angle = 0;

// commander interface

Commander command = Commander(Serial);

void onTarget(char* cmd){ command.scalar(&target_angle, cmd); }

void setup() {

// initialize encoder hardware

encoder.init();

// hardware interrupt enable

encoder.enableInterrupts(doA, doB);

// link the motor to the sensor

motor.linkSensor(&encoder);

// power supply voltage

// default 12V

driver.voltage_power_supply = 12;

driver.init();

// link the motor to the driver

motor.linkDriver(&driver);

// set control loop to be used

motor.controller = MotionControlType::angle;

// controller configuration based on the control type

// velocity PI controller parameters

// default P=0.5 I = 10

motor.PID_velocity.P = 0.2;

motor.PID_velocity.I = 20;

// jerk control using voltage voltage ramp

// default value is 300 volts per sec ~ 0.3V per millisecond

motor.PID_velocity.output_ramp = 1000;

//default voltage_power_supply

motor.voltage_limit = 6;

// velocity low pass filtering

// default 5ms - try different values to see what is the best.

// the lower the less filtered

motor.LPF_velocity.Tf = 0.01;

// angle P controller

// default P=20

motor.P_angle.P = 20;

// maximal velocity of the position control

// default 20

motor.velocity_limit = 4;

// initialize motor

motor.init();

// align encoder and start FOC

motor.initFOC();

// add target command T

command.add('T', doTarget, "target angle");

// monitoring port

Serial.begin(115200);

Serial.println("Motor ready.");

Serial.println("Set the target angle using serial terminal:");

_delay(1000);

}

void loop() {

// iterative FOC function

motor.loopFOC();

// function calculating the outer position loop and setting the target position

motor.move(target_angle);

}